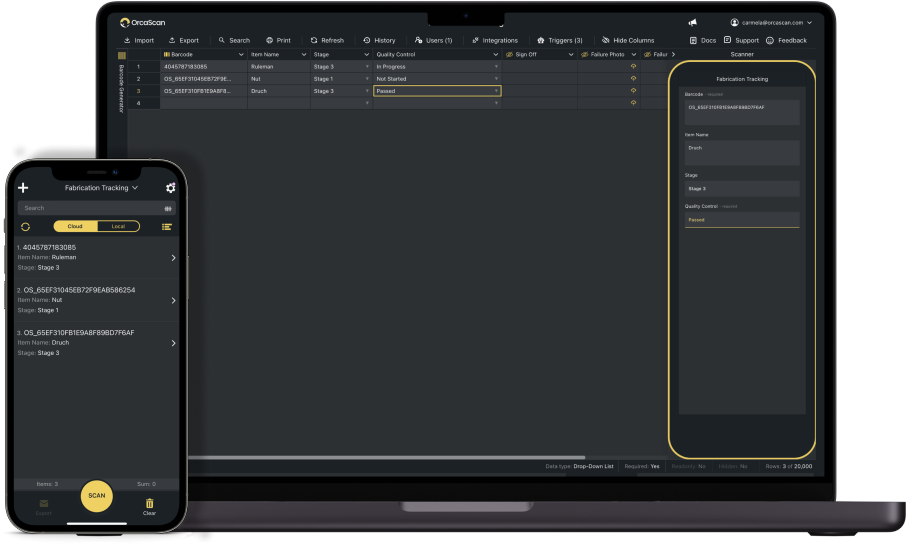

Managing and tracking components effectively is a critical part of the fabrication process, so we’ve created a flexible solution that can simplify the tracking of all your components. Whether your items come with pre-existing barcodes or you need to generate and print barcodes, our system is designed to integrate into your existing day-to-day workflow.

Getting Started with Orca Scan

- Download the Orca Scan barcode app

- Create a new sheet with the Fabrication Tracking Template

- Scan existing barcodes or generate and print new ones

- Add fields to capture additional information (if needed)

- Save the changes

With Orca Scan, your team members can update and track the progress of parts through all different stages of your workflow.

Customisation for Your Fabrication Needs

Our solution is fully customisable, so you can tailor it to track additional details for your specific fabrication process, including material type, dimensions, supplier information, tracking numbers and more.

You can also use triggers to build out bespoke workflows, enhancing the efficiency of your operations. For example, set up a trigger to get notified when your quality assurance tests pass or fail.

Why Use Orca Scan for Fabrication Tracking?

- Track a wide range of parts using existing identifiers, or generate and print your own

- Create alerts to be notified of quality assurance results at each stage

- Be notified when quality assurance tests pass or fail - with signature and photo options

- Automate quality assurance processes for consistent standards

- Compatible with your current smartphones and scanners

- Access your data from any web browser or smartphone

- Data is securely stored and accessible in the cloud

- Share data across multiple sites and locations

- Fully customisable solution to meet your needs

Efficient Multi-Site Management

If you need to manage and track components across multiple fabrication sites, then all you need to do is:

- Create a sheet using the Fabrication Tracking Template

- Add fields to capture additional information (if needed)

- Duplicate the sheet, one for each location

- Add the relevant users to the correct sheets

- Create a view for full visibility of the fabrication processes across all sites into one sheet

What if some components don’t have barcodes?

For components that do not have a barcode, you can generate and print barcode labels from the Orca Scan web and mobile applications.

You can also use triggers to build out bespoke workflows, enhancing the efficiency of your operations. For example, set up a trigger to get notified when your quality assurance tests pass or fail.

Optimising Fabrication with Orca Scan’s History Log

Orca Scan’s history log is essential for having full, long-term visibility over your fabrication process, offering detailed item tracking from receipt to production. This means you can pinpoint inefficiencies, ensure quality control, and adhere to industry standards, making it a vital tool for your operations.

Fabrication Tracking Questions?

We designed Orca Scan to streamline the tracking of fabrication parts, eliminating manual entry errors and improving efficiency. Accurate tracking in fabrication is crucial for maintaining quality and minimising waste.

If the Orca Scan Fabrication Solution doesn’t fully meet your requirements, just book a free implementation call, and we’ll help you modify the solution to meet your needs 🙏